|

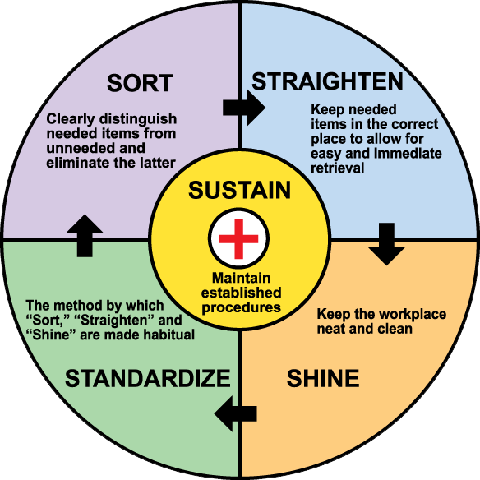

| To become a "World Class Manufacturing" company, Everspark Industries Sdn. Bhd. applies the “5S Program”. 5S stands for Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize) and Shitsuke (Sustain). By systematically incorporating 5S into our workplace we increase our efficiency and innovation. |

|

|

Everspark implements the 5S program in various ways using the following 8-step ladder:

|

1) Organize the program committee.

2) Develop a plan for each S.

3) Publicly announce the start of the program to all staff and employees.

4) Provide training and education to employees.

5) Select a day on which everybody clean up his/her own working area.

6) Select a day on which everybody organizes his/her own working area.

7) Periodically evaluate the results of 5S implementation for each department in Everspark.

8) Perform Self-Examination and Take Corrective Actions.

|

|

The 5S program communicates our vision of no searching, no delays, no idling, no obstruction, no extras, no injuries, and no waste. Through the 5S program we are able to fully utilize all of our internal and external resources as well as gradually increase the standards and productivity of the company.

|

|

Staff and employee safety will be strictly considered. In addition, faster response times, improved communications, more responsiveness, and quicker setups are value added features which benefit the customer via implementation of the 5S program within Everspark. The 5S program is a tool with which to begin, support, and sustain a lean and productive journey.

|

|

Everspark conducts official quarterly visits wherein a member of top management inspects each work area to ensure it adheres to the standards set out in the 5S program. Thanks to a reward system, workers look forward to and enjoy these visits. Top management uses checklists as score sheets and encourage friendly competition amongst workers for the most clean, organized, or innovative work area. In addition, top management also shares up-to-date progress of all improvement so that workers can take pleasure in their efforts. Regular public announcements and staff meetings reinforce our commitment to the 5S program throughout the company.

|

|